-

UHP EP TUBE:

UHP EP TUBE:

Manufacture Process:Mother Pipe---Special Cold Drawing----Bright Annealing----Electro Polishing----Passivation----Inspection----Super Mechanical Cleaning----N2 Purge----Packaging

Products range:1/4”—600A; 1/4”-4” seamless EP tubes;1”-600A weld EP tubes;

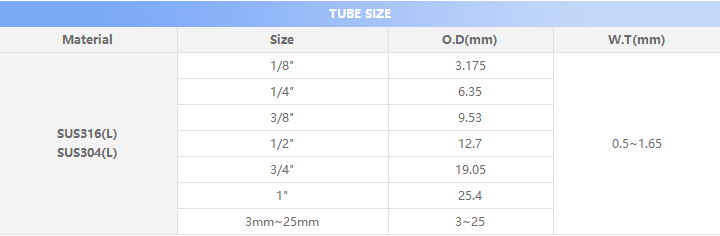

Products wall thickness and tolerances:

Normal Size 1/4”-1” : 0.89T, 1.0T, 1.24T, 1.65T; 15A-600A as:5S and 10S standard;

Wall thickness tolerances:1/4”-300A: ±10%; 350A-600A: -12.5%-+15%;

Surface Ra:1/4”-600a” :Ra≤5-10u-in(AMERICA);

Oil and Particle standard:Oil≤0.01mg/ft2; Particle≤above 0.1um 5pcs;

Dissolution Ion:NO

Basic raw materials: control of 15 types of elements, all of which comply with ASTM269 and JIS G3459 standards, with stricter control;

Cleaning and Grease removal process, check to see BUKWANG TECH CO., LTD.

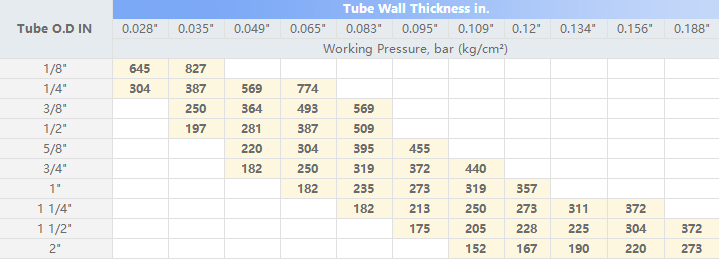

High pressure tube/meter tube:

Pressure range:

1. Fully cold-rolled 304 or 316 stainless steel tubes, in accordance with ASTM A269;

2. Common pressure range: -28-40 ° c, allowable pressure value: 1380bar (137.8mpa), in line with the standard: ANSI B31.3;

3. Maximum allowable pressure: 5175bar (516.7mpa);

Note: the above high-pressure pipe/meter pipe is mainly used in aerospace, shipbuilding, automobile and other fields;

Coil tube:

The upper coil diagram should be used in the main electronic semiconductor;

EP tube picture( BK) BA tube picture( JMHOLIC) MP tube picture(JMHOLIC)